Niviuk R-Bus (PAST MODEL)

Select all options to view stock availability

Superseded by the Niviuk R Bus 2

The best part of an adventure is to share it. This is the first Niviuk tandem paramotor wing for all types of trikes and foot-launched dual PPGs.Technical data

Size |

31 |

34 |

37 |

40 |

||

| Cells | Number | 55 | 55 | 55 | 55 | |

| Closed | 8 | 8 | 8 | 8 | ||

| Box | 35 | 35 | 35 | 35 | ||

| Flat | Area | m2 | 31 | 34 | 37 | 40 |

| Span | m | 12.94 | 13.55 | 14.14 | 14.7 | |

| Aspect Ratio | 5.4 | 5.4 | 5.4 | 5.4 | ||

| Projected | Area | m2 | 26.97 | 29.58 | 32.19 | 34.8 |

| Span | m | 10.56 | 11.06 | 11.54 | 12 | |

| Aspect Ratio | 4.14 | 4.14 | 4.14 | 4.14 | ||

| Flattening | % | 15 | 15 | 15 | 15 | |

| Chord | Maximum | m | 2.97 | 3.11 | 3.24 | 3.37 |

| Minimum | m | 0.65 | 0.68 | 0.71 | 0.74 | |

| Average | m | 2.40 | 2.51 | 2.62 | 2.72 | |

| Lines | Total meters | m | 398 | 417 | 426 | 444 |

| Height | m | 7.7 | 8.06 | 8.41 | 8.75 | |

| Number | 288 | 288 | 288 | 288 | ||

| Main | 3+1/5/3/2 | 3+1/5/3/2 | 3+1/5/3/2 | 3+1/5/3/2 | ||

| Risers | Number | 4 | A+A'/B/C/D | A+A'/B/C/D | A+A'/B/C/D | A+A'/B/C/D |

| Trimmers | mm | 105 | 105 | 105 | 105 | |

| Accelerator | NO | NO | NO | NO | ||

| Course Correction | YES | YES | YES | YES | ||

| Top Speed | 350kg | km/h | 74 (±2) | 73(±2) | 72(±2) | 71(±2) |

| Min. Sink | 350kg | m/s | 1.6 | 1.6 | 1.6 | 1.6 |

| Total weight recommended in flight | Minimum | kg | 100 | 120 | 150 | 210 |

| Maximum | kg | 410 | 440 | 470 | 500 | |

| Glider weight | kg | 6.6 | 7.1 | 7.6 | 8.1 | |

| Certification | 8G max. 328kg | EN 926-1 | EN 926-1 | EN 926-1 | EN 926-1 | |

| 5.25G max. 450kg | DGAC | DGAC | DGAC | DGAC | ||

| 5.25G max. 500kg | LOAD TEST | LOAD TEST | LOAD TEST | LOAD TEST | ||

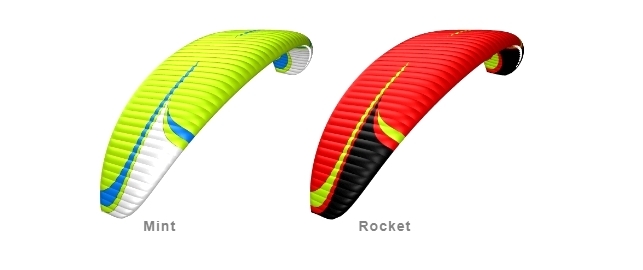

Colours

Standard colours: Mint, Rocket

Custom colours are available.

Package Includes

- R-Bus wing

- Inner bag

- Compression straps

- Riser cover

- Repair kit

Note: Backpack not included

Optional extras

R-Bus: The great traveller

The weight of a unique experience

The R-Bus has the capacity to carry loads up to 500 kg and it is eager to discover new areas and flying experiences. Amazing strength translates into stability and comfort for both pilot and passenger.

Easy to control in the air and on the ground

Solid but agile, it also permits a uniform inflation and rapid and progressive wing loading. Efficiency is assured from the first to the last moment, resulting in take-offs and landings that are simple, fast and accurate.

Niviuk DNA

Like all Niviuk wings, the R-Bus is characterised by performance, quality and great flight behaviour. Experience and share all the benefits of this new wing concept. A great traveller ready for great journeys!

More about R-Bus

The R-Bus is the first Niviuk tandem paramotor wing designed for use with a trike and it can carry loads up to 500 kilograms. Also suitable for lighter rigs and foot-launched PPG tandems, the new R-Bus was conceptualised to become the ideal tool for both professional and recreational flights.

It is a highly robust, stable and durable wing. It also features excellent wing loading and energy retention for comfortable, safe takeoffs and landings for both pilot and passenger.

The reinforced internal structure, as well as the optimised line configuration, means the load is perfectly distributed and balanced and this makes this wing capable of carrying up to 500 kg. Due to their lightweight nature, the incorporation of Nitinol rods in the profile also reduces the inertia and means a stiffer, crease-free leading edge to reduce parasitic drag.

However, the first step to an excellent flight experience is a good takeoff. The design of the line distribution permits a uniform inflation and the wing rises quickly, accurately and without the tendency over-shoot. A perfectly controllable launch phase is made possible thanks to the A Assist System, which allows the pilot to fix the A-risers to the trike to keep their hands free to comfortably handle the brake controls. On the other hand, the increased lift generated by the aerofoil enables excellent wing loading, and as a result neither long distances, high speeds or high engine power are required during takeoff. Thanks to this, neither high speed nor high engine power are required during takeoff. The R-Bus allows both pilot and passenger to quickly and easily take flight, even in less favourable conditions.

The comfort factor is also reflected in the degree of manoeuvrability of the wing. Its dual steering system enables the pilot to steer and turn efficiently without requiring much effort: the wing has both the main brake and a high-speed tip steering which allows the pilot to turn without pulling the brake, avoiding profile deformation and, as a result, a decrease of speed and performance. Also, it is a very efficient tool to compensate for the natural equal and opposite effect caused by engine inertia or torque.

The R-Bus is also equipped with a high efficiency profile, offering excellent top and cruising speeds. With the new built-in Trim Adjustor, the pilot can accurately control both the direction and speed, regardless of wing-loading.

Another strength of the R-Bus is its high degree of stability (also with light loads). Efficient glide means reduced fuel consumption and it gives the wing excellent energy retention and easy roundout for soft landings. In the case of engine failure, the reduced sink rate is big bonus for safety (-2.5 m/s for a wing-loading of 420 kg).

Suitable for a wide range of paramotors and trikes, the R-Bus is available in two sizes: 37 m2 (ideal for light trikes, windy areas or foot-launched takeoffs with moderate wind) and 40 m2 (perfect for heavier trikes).

Share and enjoy all the advantages of this new wing with pure Niviuk DNA.

In case of a trike designed to have elevated hang points, the R-Bus accessories include extra brake lines and the high speed tip is one meter longer. The pilot should exchange and adjust these as required.

The fabric, lines, risers and wing size can all be changed to customise and adapt the model to suit your needs and preferences. Contact Flybubble and we will personally explore all the possibilities.

Technologies

RSP (Reflex System Profile)

The highly efficient Reflex System Profile (RSP) unlike conventional reflex designs requires less engine power to achieve greater thrust, thus resulting in lower fuel consumption, more autonomy and higher overall motor efficiency.

The RSP profile improves gliding, speed and safety.

SLE (Structured Leading Edge)

The SLE provides more rigidity and stability along the span of leading edge but also allows full flexibility along the both the vertical and horizontal axis of each open cell. The SLE ensures ease of movement on the ground and high security in the air during turbulence and whilst flying at speed.

With the SLE system there is no longer a need to use large amounts of mylar material to achieve leading edge reinforcement. This reduction in material has reduced the weight of the leading edge and the result is precise handling on the ground and easier launches.

The SLE also helps to prevent deformation of the leading edge and therefore with correct care will extend the life and efficiency of your glider.

In addition to the SLE, Niviuk work on new geometry and layout of the internal reinforcement. This new internal restructuring offers better overall cohesion of the glider and incredible stability during turbulence.

TNT (Titanium technology)

Constantly innovating, Niviuk always are on the hunt, looking for the latest and best materials to helps us design optimal products. For this reason, and after an extensive evaluation of its benefits and qualities, they decided to be the first manufacturer to use Nitinol in Niviuk's glider line.

Benefits

Nitinol is an alloy of 50% nickel and 50% titanium. This technology in Niviuk rods offers three major advantages of optimizing the performance of a paraglider, compared to those made out of Nylon:

- The addition of Nitinol rods in the profile has the immediate result of substantially reducing the overall weight of the wing by about 13%.

- Nitinol has two very specific properties: shape memory and super elasticity. The flexible rods always regain their functional optimal shape, even after tight bending, no wrinkles or residual mechanical alterations affect their integrity.

- As a result, the wing's leading edge is then preformed on the ground and allows a uniform progressive inflation phase to take place, which considerably facilitates the take-off. The wing surface is perfectly taut, wrinkle free and without parasitic cloth movements, the glide is thus optimized in all flight phases.

In addition, the rods are outfitted with plastic protectors at their ends to prevent fabric damage.

3DL (3D Leading Edge)

Adding an extra seam to the leading edge on the span axis of the glider helps to shape a compact 3D profile and have better connections to the new 3DP front panel’s layout.

When sewn together, the fabric pattern orientation and panel positioning are taken into account to avoid creases and ultimately obtain a perfect load distribution. As a result the glider profile is cleaner, to the benefit of performance and durability.

The application of this innovation to the profile is key to reaching the perfect shape from 2D to 3D.

3DP (3D Pattern Cut Optimisation)

Niviuk paragliding and paramotor wing designs have changed significantly over time; hence considerably affecting the leading edge shape.

The latest glider generation requires a new pattern design and an optimized fabric cutting process.

The new leading edge arrangement calls for each cell panel to be manufactured independently from the others according to the final wing layout positioning, resulting in a crease-free surface with better fabric tension. Niviuk use the analogy of a rugby ball made of different sewn individually shaped panels to obtain the perfect characteristic oval shape without wrinkles.

An optimised process is used to cut the fabric in a specific directional angle, depending on each panel’s final location. If the cloth pattern is correctly aligned with the load axis, the material is deformed to a minor degree to benefit the aerodynamic properties of the leading edge.

The application of this innovation, together with the 3DL, is key for reaching the optimal modelled form and function from 2D to 3D.

RAM Air Intake

Constant improving

Evolution and constant improving in all Niviuk products is the essence of the DNA of Niviuk’s R&D team. Thanks to the new technologies created over recent years, Niviuk has conceived new and more evolved and higher performing gliders. In this context the RAM Air Intake technology should be pointed out.

The evolution of RAM Air Intake

The RAM provides optimised internal pressure for better airflow; therefore, the glider is more compact at any angle of incidence and all trim settings. It reduces the risk of experiencing a collapse while bringing better control and stability to the overall structure. Moreover, the RAM improves the wing’s turbulence buffering ability.

Technology, a priority for Niviuk

For us, giving importance to small details means continuing working towards Niviuk goals. It means keeping focused on technology as a priority. It means provide innovation and quality to all pilots.

Learn more about Niviuk Paraglider Technologies

How to use the Trimmers on the R-Bus

Reviews

"Our first flight in R-Bus was an enormous pleasure. A calm and safe flight with a high quality wing, which is precise, stable and definitely high performance. Many thanks!"

- Fabrice Fuentes

"After producing many paramotor wings for solo pilots, Niviuk completely fulfills the expectations of tandem pilots, especially those who fly with a lot of weight."

- Paramoteur+ magazine review, Read the full review (in french)

Downloads

Manual

R-Bus Eng. Esp.

| Condition | New |

|---|---|

| EN Certification | EN 926-1 Load Test |

| Other Certification | DGAC |

| Model Status | Past model |

Standard UK delivery - £3.95 / FREE on orders over £100.

Outside the UK - delivery calculated at checkout (based on the total order value and your delivery address).

We use Royal Mail, Parcelforce Worldwide and other courier companies (e.g. DHL, DPD) depending on shipment value, weight, destination etc.

For more information, please view our order and delivery FAQs page.

If you are not 100% satisfied with your order, you have 14 days from the day of delivery to request a refund.

Delivery costs will not be refunded and you will be responsible for the delivery cost to return the order.

For more information, please read our returns and exchanges policy.