Triple Seven Gambit (PAST MODEL)

Select all options to view stock availability

This is an old model. See current Competition Paragliders

The Triple Seven Gambit is an uncompromising paraglider, designed for winning top-level competitions together with the best pilots in the world. In spite of this, it is still very much a Triple Seven wing; fun, exciting, helpful, easy and FAST.Technical Data

Size |

XXS |

XS |

S |

M |

L |

| Number of cells | 137 | 137 | 137 | 137 | 137 |

| Projected area (m2) | 16.5 | 17.5 | 19.02 | 20.17 | 21.9 |

| Flat area (m2) | 19.5 | 20.6 | 22.4 | 24.1 | 25.8 |

| Flat aspect ratio | 7.9 | 7.9 | 7.9 | 7.9 | 7.9 |

| In-flight weight range (kg) | 80-90 | 85-95 | 90-105 | 101-116 | 110-125 |

| Certification LTF/EN | CCC | CCC | CCC | CCC | CCC |

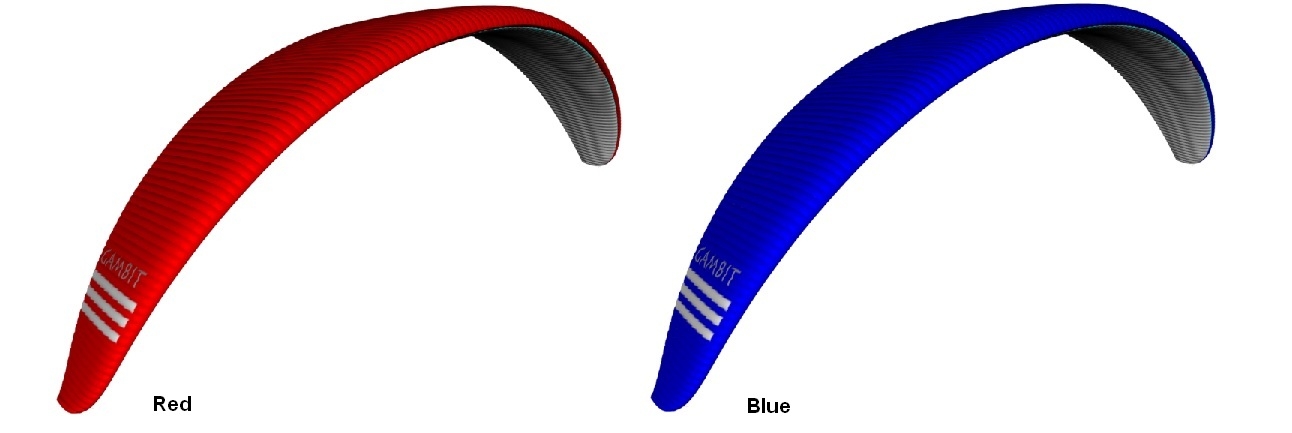

Colours

Standard colours: Red, Blue

Package Includes

- Glider

- Rucksack Box 150

-

Glider concertina bag

-

Repair kit

When results matter CCC Class

Compared to contemporary designs in this segment, the Gambit is an easy wing to fly well; and it is easy to fly faster too. It is a very solid design and will allow the right pilot to cruise through turbulence with confidence, even at its very considerable top speed.

Main Features

Segmented Diagonal Technology

When paraglider manufacturers first started using diagonal ribs inside the canopies to reduce the number of suspension points and lines, the default method was to have just one (perforated) diagonal running almost from cell opening back to the C or D suspension point and beyond. Triple Seven was quick to notice that this method was sub-optimal particularly in the leading-edge region of the canopy – as the diagonal curved around the inside of the leading edge, the cloth would get warped and the load distribution exceedingly difficult to control. Triple Seven's solution is to employ several separate diagonal ribs (see illustration), each shaped and cut precisely for the loads it is subjected to in flight. Not only does this extra effort translate into better load distribution and fewer wrinkles, but it also increases canopy integrity in turbulence, to the benefit of real-life glide performance especially at higher speeds.

Load Distribution Optimization

One of the main challenges in paraglider design is to make the aircraft, sewn from soft materials and filled with nothing but air, into a “solid” wing that will maintain its optimal shape even while flying through midday thermals and wind shears. Making this even more complicated is the fact that in order to improve performance there is no way around reducing drag; after all, Triple Seven all know that the common name for gliding performance of unmotorised aircraft is L/D – lift to drag ratio. As lift for a wing equals aircraft weight, the only way to make it go further is by cutting drag, so Triple Seven keep reducing external things which help the wing maintain its shape, not least by reducing line consumption.

Drag is also caused by canopy wrinkles; just one more reason to make canopies as wrinkle-free as at all possible.

Enter the Triple Seven Load Distribution Technology

Consisting of a thin Nylon “rod” sewn into each cell wall in a carefully designed wave pattern, the Load Distribution Technology distributes the loads from each line level across the whole chord of the wing, making the wing so much more true to its shape regardless of what the air is doing around it. This translates into a higher resistance to collapses, better energy retention and not least significantly improved gliding performance through turbulent air – and the best part is, with the very thin diameter of the “rods” it doesn’t impede the packing of the wing at all.

Visual Design Optimization

Although all Triple Seven's wings look great from a graphical perspective, there’s more to the design than meets the eye. Each and every seam (except the “7” logo on the wingtips) has been placed precisely where it is for a reason, and there are no more seams in the canopy than necessary for the optimal panel tensioning everywhere. The reason Triple Seven mention this is if you design for looks rather than for efficiency you often end up with many more seams than you should ideally have, and every single one will increase the total air permeability of the canopy. In extreme cases this may lead to porosity issues at readings that wouldn’t normally be considered critical – if too much air is escaping via the many seams, then smaller increases in porosity in the individual panels may cause the whole wing to fall over the edge of what is still flyable.

When flying a Triple Seven wing you can rest assured that none of the design elements has been incorporated out of vanity – there are only technical solutions. Fortunately, the discerning pilot will instinctively associate efficiency with attractive!

Back Position (air) Intake

On conventional paragliders, the location of the cell openings is always a compromise. The cell openings on paragliders must be located at the separation point (the place where the airflow separates into a part that travels OVER the wing, and another part that travels UNDER the wing) and because there is just one separation point, the cell openings must be either very large or placed either at the separation point for trim speed, top speed or somewhere in between.

At Triple Seven, ALL Triple Seven's wings have been incorporating dual separation point aerofoils since the very first model – Triple Seven call it the Back Position Intake. On Triple Seven wings the cell opening is located right between the two separation points, allowing us to make it smaller while maintaining maximum inflow and thus maximum internal pressure at all angles of attack. With smaller cell openings and greater internal pressure, the collapse tendency at all speeds is significantly reduced, and the brake authority is increased – a big brake input from behind momentarily increases the pressure at the leading edge because the air cannot escape through the small openings, and this makes the leading edge more solid, less collapse-prone for the experienced pilot.

But due to the nature of the BPI even inexperienced pilots benefit from the BPI technology – the stall characteristics are significantly better, and the wing collapses much less in the first place. Triple Seven has also found that BPI aerofoils have better energy retention, making them more efficient in turbulent air – they aren’t as susceptible to being stopped in their tracks by sudden surges, something that makes them convert bumps along the way into altitude much better than conventionally designed paragliders.

Triple Seven was the first manufacturer to employ BPI technology to the full model range, and Triple Seven's extensive experience with this game-changing technology is just one more reason why Triple Seven believe that a Valic-designed wing will make YTriple Seven's flying more rewarding every time you take your wing out of its bag. At the end of the day, this is precisely what paragliding is about for us – getting the most out of every flying opportunity, regardless of your personal goals!

Optimised Cross Vents

As paraglider canopies grow increasingly complex inside, the number of components in each wing grows as well. If you sometimes wonder why the prices seem to always take a small hike upwards with each new model range, this is the reason for it – a modern canopy is simply far more complex to put together than a five-year-old model was.

But with increasing complexity, one would normally expect the weight to go up as well, and one of the main challenges Triple Seven's designers face when working on new products is to make sure this isn’t the case. A heavier canopy is bad on just about every level, from the basic premise that you still have to carry it on your back, to the fact that heavy canopies launch less readily, and have less enticing handling once in the air. So the challenge is to include all the extra elements inside the wing, but make sure they are as minimal in every way as at all possible. When you look through the (small) cell openings of a Triple Seven wing you’ll notice that all the ribs, and the diagonal ribs, in particular, are very elaborately designed and shaped, the cross ports following the stress lines very accurately, and also that they’re split up into several smaller sections. Through this extra complexity, Triple Seven has managed to get the best of both worlds; the lightness that Triple Seven feel is essential for obtaining the handling and safety characteristics Triple Seven want, and the rigidity and form-wise integrity that gives Triple Seven's wings their hallmark class-bursting performance under real, active flying conditions. It is not a very visible brand characteristic when you see a Triple Seven glider in the air or on the ground, but it is VERY easy to recognise the resulting performance and handling benefits as soon as you take to the air!

Materials

| Canopy | Material |

| Leading-edge | Dominico 30 |

| Top surface | Porcher Skytex 32 |

| Internal construction | Porcher Skytex 27 hard, Skytex 40 hard |

| Bottom surface | Porcher Skytex 27 |

| Reinforcements | Nitinol |

| Lines | Material |

| Upper cascades | Edelrid A8000U (70, 50, 25), Liros DC 35 |

| Middle 1 cascades | Edelrid A8000U (130, 90, 70, 50, 25), Liros DC 35 |

| Middle 2 cascades | Edelrid A8000U (90, 50, 25), Liros DC (301, 201, 161) |

| Main lines | Edelrid A8000U 70, Liros DC (401, 201, 161) |

| Stabilo | Edelrid A9020-030 |

Downloads

| Condition | New |

|---|---|

| EN Certification | CCC |

| Model Status | Past model |

Standard UK delivery - £3.95 / FREE on orders over £100.

Outside the UK - delivery calculated at checkout (based on the total order value and your delivery address).

We use Royal Mail, Parcelforce Worldwide and other courier companies (e.g. DHL, DPD) depending on shipment value, weight, destination etc.

For more information, please view our order and delivery FAQs page.

If you are not 100% satisfied with your order, you have 14 days from the day of delivery to request a refund.

Delivery costs will not be refunded and you will be responsible for the delivery cost to return the order.

For more information, please read our returns and exchanges policy.