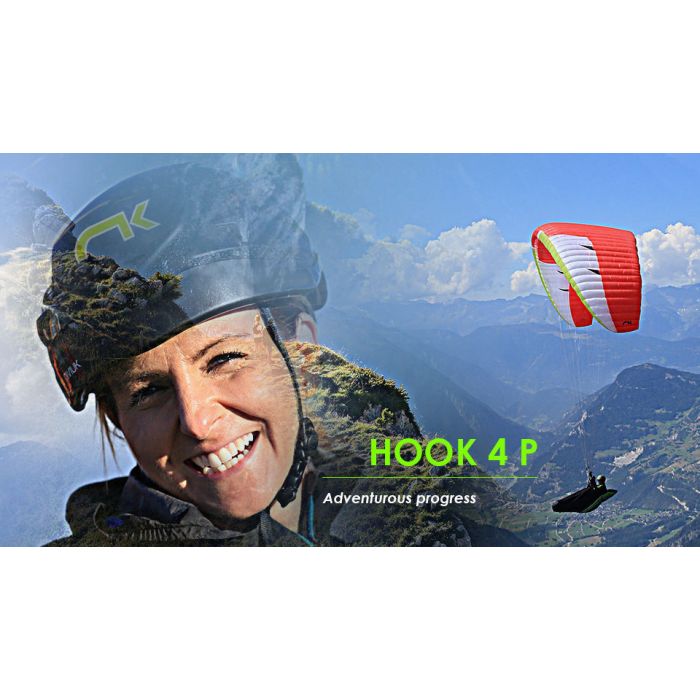

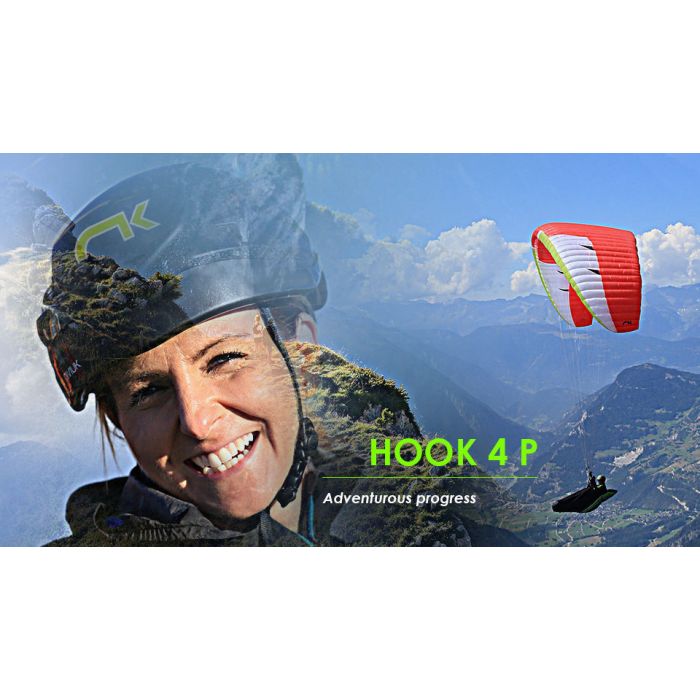

Up to 1.4 kg less

Less weight and volume for more comfort and enhanced passive safety. Weighing up to 1.4 kg less in comparison to the conventional model, the Hook 4 P features a more intuitive, sweet and responsive handling.

Intermediate and more versatile

Improve your piloting skills while discovering new possibilities for flight. Start and progress to your own hike & fly or vol-biv adventures. Now you can too!

Accessible performance

Keep enjoying all the performance and potential of the standard Hook 4. Extremely simple launch characteristics, effective glide and responsive and precise in turns.

More about Hook 4 P

The Hook 4 P is the lightweight version of our progression wing, the Hook 4. With up to 1.4 kg less weight, this new model is ideal for explorers who after making their debut in the world of paragliding decide to continue progressing with each flight, as well as for more experienced adventurers who prefer an intermediate, very safe wing.

With the new Hook 4 P you too can discover and enjoy hike & fly or vol-biv adventures. A wing with an extremely reduced weight and volume so that from now on you can choose when, where and how to advance.

To achieve a reduction of nearly a kilo and a half, the Hook 4 P has been made of lightweight materials: Porcher Skytex 27g fabric, Nitinol rods and Dyneema risers, which are much lighter than those used in conventional wings. Additionally, unlike the conventional version, the Hook 4 P has thinner, unsheathed lines.

All these details make for a more comfortable wing, not only when carrying it, but during every phase of flight. The reduced wing weight allows a much easier, calmer and progressive inflation - even in nil-wind. Once in the air, the Hook 4 P inherits from the Hook 4 its excellent efficiency and good gliding ability to carve through the air. More sensitive and with less inertia, the Hook 4 P provides even more feedback, a key feature to allow you to feel and maintain in control of the wing while you progress with complete safety.

Hook 4 P - less weight and volume for complete freedom.

Like all P series gliders, the Hook 4 P comes with IKS 1300 kg (a connecting system to join the lines to the risers) as standard. Being 25 times lighter (0.2 g), the IKS system has a load-bearing break point of 1300 kg, compared to the 800 kg of the classic maillons. IKS is an ultralight connection system specially designed for mountain and lightweight equipment.

The fabric, lines, risers and wing size can all be changed to customise and adapt the model to suit your needs and preferences. Contact us and we will personally explore all the possibilities.

Technologies Hook 4 P

SLE (Structured Leading Edge)

The SLE provides more rigidity and stability along the span of leading edge but also allows full flexibility along the both the vertical and horizontal axis of each open cell. The SLE ensures ease of movement on the ground and high security in the air during turbulence and whilst flying at speed.

With the SLE system there is no longer a need to use large amounts of mylar material to achieve leading edge reinforcement. This reduction in material has reduced the weight of the leading edge and the result is precise handling on the ground and easier launches.

The SLE also helps to prevent deformation of the leading edge and therefore with correct care will extend the life and efficiency of your glider.

In addition to the SLE, we work on new geometry and layout of the internal reinforcement. This new internal restructuring offers better overall cohesion of the glider and incredible stability during turbulence.

TNT (Titanium technology)

Constantly innovating, we always are on the hunt, looking for the latest and best materials to helps us design optimal products. For this reason, and after an extensive evaluation of its benefits and qualities, we decided to be the first manufacturer to use Nitinol in our glider line.

Benefits

Nitinol is an alloy of 50% nickel and 50% titanium. This technology in our rods offers three major advantages of optimizing the performance of a paraglider, compared to those made out of Nylon:

- The addition of Nitinol rods in the profile has the immediate result of substantially reducing the overall weight of the wing by about 13%.

- Nitinol has two very specific properties: shape memory and super elasticity. The flexible rods always regain their functional optimal shape, even after tight bending, no wrinkles or residual mechanical alterations affect their integrity.

- As a result, the wing's leading edge is then preformed on the ground and allows a uniform progressive inflation phase to take place, which considerably facilitates the take-off. The wing surface is perfectly taut, wrinkle free and without parasitic cloth movements, the glide is thus optimized in all flight phases.

In addition, the rods are outfitted with plastic protectors at their ends to prevent fabric damage.

DRS (Drag Reduction Structure)

With the Drag reduction Structure technology, the trailing edge has been reinforced with small ribs that that makes this part of the glider flatter in order to spread the pressure out evenly. It means better air-flow and less drag on this important part of the glider.

The addition of these small ribs gives the glider exceptional handling (better and more efficient when turning) and more control and precision. We are convinced that the key to achieve better products is the innovation. Only if we go on looking for new possibilities, we will be able to reach our main goal: enhance the experience of the pilots.

3DL (3D Leading Edge)

Adding an extra seam to the leading edge on the span axis of the glider helps to shape a compact 3D profile and have better connections to the new 3DP front panel’s layout.

When sewn together, the fabric pattern orientation and panel positioning are taken into account to avoid creases and ultimately obtain a perfect load distribution. As a result the glider profile is cleaner, to the benefit of performance and durability.

The application of this innovation to the profile is key to reaching the perfect shape from 2D to 3D.

3DP (3D Pattern Cut Optimisation)

Our paragliding and paramotor wing designs have changed significantly over time; hence considerably affecting the leading edge shape.

The latest glider generation requires a new pattern design and an optimized fabric cutting process.

The new leading edge arrangement calls for each cell panel to be manufactured independently from the others according to the final wing layout positioning, resulting in a crease-free surface with better fabric tension. We could use the analogy of a rugby ball made of different sewn individually shaped panels to obtain the perfect characteristic oval shape without wrinkles.

An optimised process is used to cut the fabric in a specific directional angle, depending on each panel’s final location. If the cloth pattern is correctly aligned with the load axis, the material is deformed to a minor degree to benefit the aerodynamic properties of the leading edge.

The application of this innovation, together with the 3DL, is key for reaching the optimal modelled form and function from 2D to 3D.

IKS (Interlock System)

The IKS is an ultralight connection system specially designed for mountain and lightweight equipment. With less weight than the traditional delta maillon and much more resistant.

Moreover, it is fitted with a locking system providing greater efficiency at maximum load. Dyneema braids stitched together with a locking strap.

P-Series gliders (light), Skin P and Artik P, come as standard with the IKS 1300 kg, a version made to connect the lines to the risers. Being 25 times lighter (0,2 g), this IKS model has a load bearing braking point of 1300 kg compared to the 800 kg of the classic maillon.

Notice: the IKS 1300 kg system was not designed nor proven to connect the risers to the harness and/or a rescue parachute to the harness.

RAM Air Intake

Constant improving

Evolution and constant improving in all our products is the essence of the DNA of Niviuk’s R&D team. Thanks to the new technologies created over recent years, we have conceived new and more evolved and higher performing gliders. In this context the RAM Air Intake technology should be pointed out.

The evolution of RAM Air Intake

The RAM provides optimised internal pressure for better airflow; therefore, the glider is more compact at any angle of incidence and all trim settings. It reduces the risk of experiencing a collapse while bringing better control and stability to the overall structure. Moreover, the RAM improves the wing’s turbulence buffering ability.

Technology, a priority for Niviuk

For us, giving importance to small details means continuing working towards our goal. It means keeping focused on technology as a priority. It means provide innovation and quality to all pilots.

Technical data

Size

|

|

21

|

23

|

25

|

27

|

| cells |

number |

52 |

52 |

52 |

52 |

| cells |

closed |

8 |

8 |

8 |

8 |

| cells |

box |

23 |

23 |

23 |

23 |

| flat |

area (m2) |

21 |

23 |

25 |

27 |

| flat |

span (m) |

10,65 |

11,15 |

11,62 |

12,08 |

| flat |

aspect ratio |

5,4 |

5,4 |

5,4 |

|

| projected |

area (m2) |

17,85 |

19,55 |

21,25 |

22,95 |

| projected |

span (m) |

8,45 |

8,84 |

9,22 |

9,58 |

| projected |

aspect ratio |

4 |

4 |

4 |

4 |

| flattening |

% |

15 |

15 |

15 |

15 |

| cord |

maximum (m) |

2,47 |

2,58 |

2,69 |

2,8 |

| cord |

minimum (m) |

0,49 |

0,52 |

0,54 |

0,56 |

| cord |

average (m) |

1,97 |

2,06 |

2,14 |

2,23 |

| lines |

total meters (m) |

208 |

218 |

227 |

236 |

| lines |

height (m) |

6,5 |

6,8 |

7,09 |

7,36 |

| lines |

number |

180 |

180 |

180 |

180 |

| lines |

main |

2+1/3/2 |

2+1/3/2 |

2+1/3/2 |

2+1/3/2 |

| risers |

number (3) |

A+A'/B/C |

A+A'/B/C |

A+A'/B/C |

A+A'/B/C |

| trims |

m/m |

NO |

NO |

NO |

NO |

| accelerator |

m/m |

135 |

135 |

135 |

135 |

| total weight |

minimum (kg) |

55 |

65 |

80 |

95 |

| in flight |

maximum (kg) |

70 |

85 |

100 |

115 |

| glider weight |

kg |

3 |

3,25 |

3,6 |

3,85 |

| certification |

EN/LTF |

B |

B |

B |

B |

Downloads

Manual

Hook 4 P Eng. Fra. Esp.

Technical Data

Hook 4 P Eng. Fra. Esp.

Niviuk Hook 4 P Reviews

See Niviuk Hook 4.

![]()