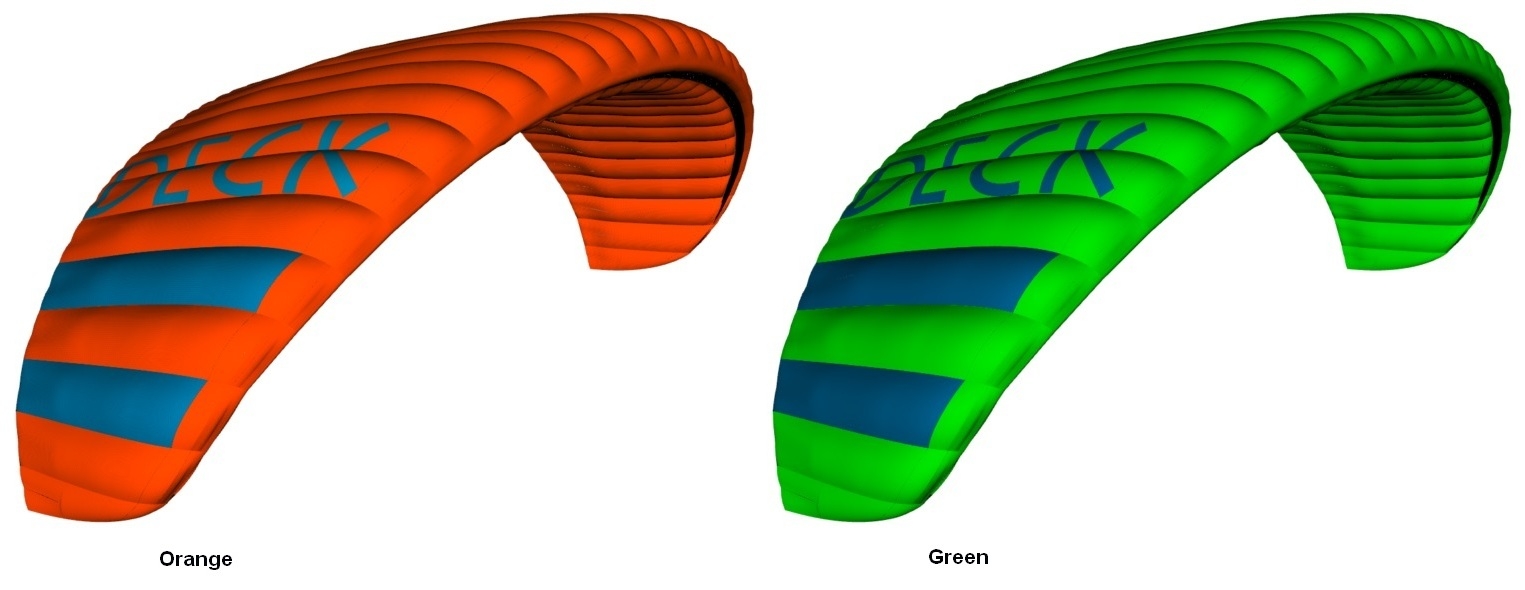

Triple Seven Deck Evo (PAST MODEL)

Select all options to view stock availability

This is an old model. See current First Paragliders

The Triple Seven Deck Evo is an EN/LTF A certified school and beginner glider, ideal for paragliding schools and newbies who are busy learning to fly and disinterested in anything that may distract them from this goal. Built tough, it is able to withstand much of the abuse that a school glider is subjected to, and will give its owner many hours of stress-free flying.Technical data

| S | M | L | |

|---|---|---|---|

| Number of cells | 29 | 29 | 29 |

| Projected area (m2) | 20.1 | 23.2 | 25.3 |

| Flat area (m2) | 24 | 27.1 | 30.5 |

| Projected span (m) | 7.85 | 8.39 | 8.85 |

| Flat span (m) | 10.27 | 11.04 | 11.58 |

| Projected Aspect Ratio | 3.06 | 3.06 | 3.06 |

| Flat aspect ratio | 4.4 | 4.4 | 4.4 |

| Glider weight (kg) | 4.5 kg | 5 kg | 5.5 kg |

| In-flight weight range (kg) | 60-85 | 80-105 | 100-125 |

| Certification LTF/EN | A | A | A |

Colours

Standard colours: Orange, Green

Options

- Men's or women's T-shirt Size

Package Includes

- Glider

- Backpack

- Inner bag

- Glider strap

- Repair kit

- T-shirt

Triple Seven Deck Evo

Triple Seven's EN A Deck was designed to help pilots fulfil the dream of flying in the safest possible way. With their students all on Triple Seven Decks, any instructor will be sure that they are in best possible hands, with state-of-the-art Triple Seven design. EN/LTF A certification means the best possible safety for the pilots, but the thoughts were everywhere, from total launch and take-off ease until the student touches down. With the Deck, instructors and students may focus on expanding the pilots’ skills, airmanship and flying knowledge.

Main Features

- Easy launch and landing characteristics

- BPI Back position intake technology

- VDO Visual design optimization

- STE smooth trailing edge

- Progressive handling and easy control characteristics

- Well-balanced wing for maximum ease of piloting

- Robust and durable design and materials

- Three liner with split A lines

- EN-A, LTF-A class

Materials

Part |

Canopy Fabric Code |

| Upper surface | DOKDO 30 DMF |

| Bottom surface | DOKDO 30 DMF |

Visual design optimisation – Triple Seven VDO technology

Although all wings look great from a graphical perspective, there’s more to the design than meets the eye. Each and every seam (except the “7” logo on the wingtips) has been placed precisely where it is for a reason, and there are no more seams in the canopy than necessary for the optimal panel tensioning everywhere. If you design for looks rather than for efficiency you often end up with many more seams than you should ideally have, and every single one will increase the total air permeability of the canopy. In extreme cases this may lead to porosity issues at readings that wouldn’t normally be considered critical – if too much air is escaping via the many seams, then smaller increases in porosity in the individual panels may cause the whole wing to fall over the edge of what is still flyable.

When flying a Triple Seven wing you can rest assured that none of the design elements has been incorporated out of vanity – there are only technical solutions. Fortunately, the discerning pilot will instinctively associate efficiency with attractive!

Back Position (air) Intake

On conventional paragliders, the location of the cell openings is always a compromise. The cell openings on paragliders must be located at the separation point (the place where the airflow separates into a part that travels OVER the wing, and another part that travels UNDER the wing) and because there is just one separation point, the cell openings must be either very large, or placed either at the separation point for trim speed, top speed or somewhere in between.

At Triple Seven, ALL their wings have been incorporating dual separation point aerofoils since the very first model – they call it the Back Position Intake. On Triple Seven wings the cell opening is located right between the two separation points, allowing Triple Seven to make it smaller while maintaining maximum inflow and thus maximum internal pressure at all angles of attack. With smaller cell openings and greater internal pressure, the collapse tendency at all speeds is significantly reduced, and the brake authority is increased – a big brake input from behind momentarily increases the pressure at the leading edge because the air cannot escape through the small openings, and this makes the leading edge more solid, less collapse-prone for the experienced pilot.

But due to the nature of the BPI even inexperienced pilots benefit from the BPI technology – the stall characteristics are significantly better, and the wing collapses much less in the first place. Triple Seven have also found that BPI aerofoils have better energy retention, making them more efficient in turbulent air – they aren’t as susceptible to being stopped in their tracks by sudden surges, something that makes them convert bumps along the way into altitude much better than conventionally designed paragliders.

Triple Seven was the first manufacturer to employ BPI technology to the full model range, and their extensive experience with this game-changing technology is just one more reason why they believe that a Valic-designed wing will make your flying more rewarding every time you take your wing out of its bag. At the end of the day, this is precisely what paragliding is about – getting the most out of every flying opportunity, regardless of your own personal goals!

Smooth Trailing Edge

The paraglider’s trailing edge is a critical part of the design for both glider handling and performance, and one where Triple Seven invest a lot of effort into perfecting it. As the paraglider is inflated, the pressure inside makes the cells billow, and the Triple Seven STE technology is there to control the billowing near the trailing edge. Too much billow in this region shortens the trailing edge in a spanwise direction and may make the canopy pitch unstable in combination with pressure changes. Besides, too much billow at this critical part of the canopy adversely affects performance, because it may cause the airflow to separate in an uncontrolled manner.

With the Triple Seven STE technology, their designers have managed to completely eliminate excessive billowing, making for a much more coherent and sharp trailing edge. This is great news for performance and handling because the solid trailing edge transmits brake line input into turns much more readily.

Designers Notes

“We were the first to introduce Back Position Intakes into the EN/LTF A class. With years of experience with this aerofoil design we already knew all the positive sides of the BPI technology, and we adapted it to attain the ideal passive handling characteristics of the Deck glider. Pitch and roll oscillations are dampened to precisely the right degree, to give students peace of mind and let them focus on the effects of the air around them. To put it as simply as we can – Deck students learn faster. I believe that the first wing a person flies is the most important one in the whole career of a paraglider pilot. It follows that my school glider, the Deck, is simply the easiest wing to launch, fly and land that you can think of. The use of advanced design elements, like the BPI and the mini-ribs, refine the Deck’s trailing edge and overall profile. This has resulted in great handling in climbs – essential for those first steps towards acquiring thermalling skills. The Deck is a confidence-inspiring glider that will help any student learn the basics of paragliding rapidly and with ease.”

Urban Valic

Downloads

| Condition | New |

|---|---|

| EN Certification | EN A |

| LTF Certification | LTF A |

| Model Status | Past model |

Standard UK delivery - £3.95 / FREE on orders over £100.

Outside the UK - delivery calculated at checkout (based on the total order value and your delivery address).

We use Royal Mail, Parcelforce Worldwide and other courier companies (e.g. DHL, DPD) depending on shipment value, weight, destination etc.

For more information, please view our order and delivery FAQs page.

If you are not 100% satisfied with your order, you have 14 days from the day of delivery to request a refund.

Delivery costs will not be refunded and you will be responsible for the delivery cost to return the order.

For more information, please read our returns and exchanges policy.