The Loft Workshop is a well-known paraglider repair and service centre based in southeast England that’s been going since 1998. They repair wings, harnesses and even kite surfing equipment. For many UK pilots, a season isn’t complete without using their services. I went along to Newhaven to learn a little more about the company, the man behind it--Mike Millwood, flying since 1986--and what goes into servicing a wing.

Insights from Mike Millwood

I asked The Loft Workshop's boss, Mike Millwood a few questions starting with his history in freeflight...

How did you get into flying?

I worked on a farm in Chailey. When ‘The Mad Farmer’ (Dave Watts) turned up with his Microlight and started using our fields as a take-off, it got me interested, so in 1986 I started Hang Gliding, then after 2 years of that got into Paragliding.

How did you get into repairing Paragliders?

I began with Sky Systems back in ’88 initially making hang gliding accessories, then this changed to paragliding equipment including harness (winters making these really honed my machine skills, something you can’t learn overnight) and gliders! after a time working with a freefall parachute rigger I could then repair paragliders, this work allowed me to schedule my time around flying. It has however taken over rather from flying these days …

How many hours a year of flying do you manage?

Not a lot, I get out perhaps a couple of times a year, my 12 and 14-year-old kids take up most of my free time!

How many reserves have you repacked?

Probably around 4,000.

What are your favourite places to fly?

I always enjoyed Combe for its xc potential, and Merthyr is also a great launch point. Also our local sites Ditchling and the Dyke, when it’s good you can’t beat the UK.

That said, I also love the Victorian Alps in Australia, mainly at a take-off called Corryong.

You moved from a small barn in Firle into larger premises in Newhaven 2 years ago; How is the new space working out for The Loft?

It’s really good, we are busier, we can simultaneously work on servicing two wings , repacking reserves plus have Claire working the sewing machines on repair jobs. We are much more efficient, however even though we can get far more work done than before we’re never short of a work waiting to be put through the system...

How many of you work together?

Myself, Eddy, Claire, Ross working part time and we have a further position currently open – let us know if you’re interested.

How important are inflatable bags for folding the wing?

They are only really useful for comp wings with the longer batons.

Do you notice a difference in longevity with the new light weight wings?

The early ones occasionally suffered as the manufacturing of the cloth was not always very consistent, sometimes the fabric would delaminate or wear quickly, however nowadays they tend to last very well as long as they are looked after and in this respect the tips for looking after a wing are even more important.

What’s involved in a wing service?

Visual check of all the lines with a particular emphasis on the common wear points such as maillon loops, stitches, connection points. This is done visually and by feel for both unsheathed and sheathed lines…

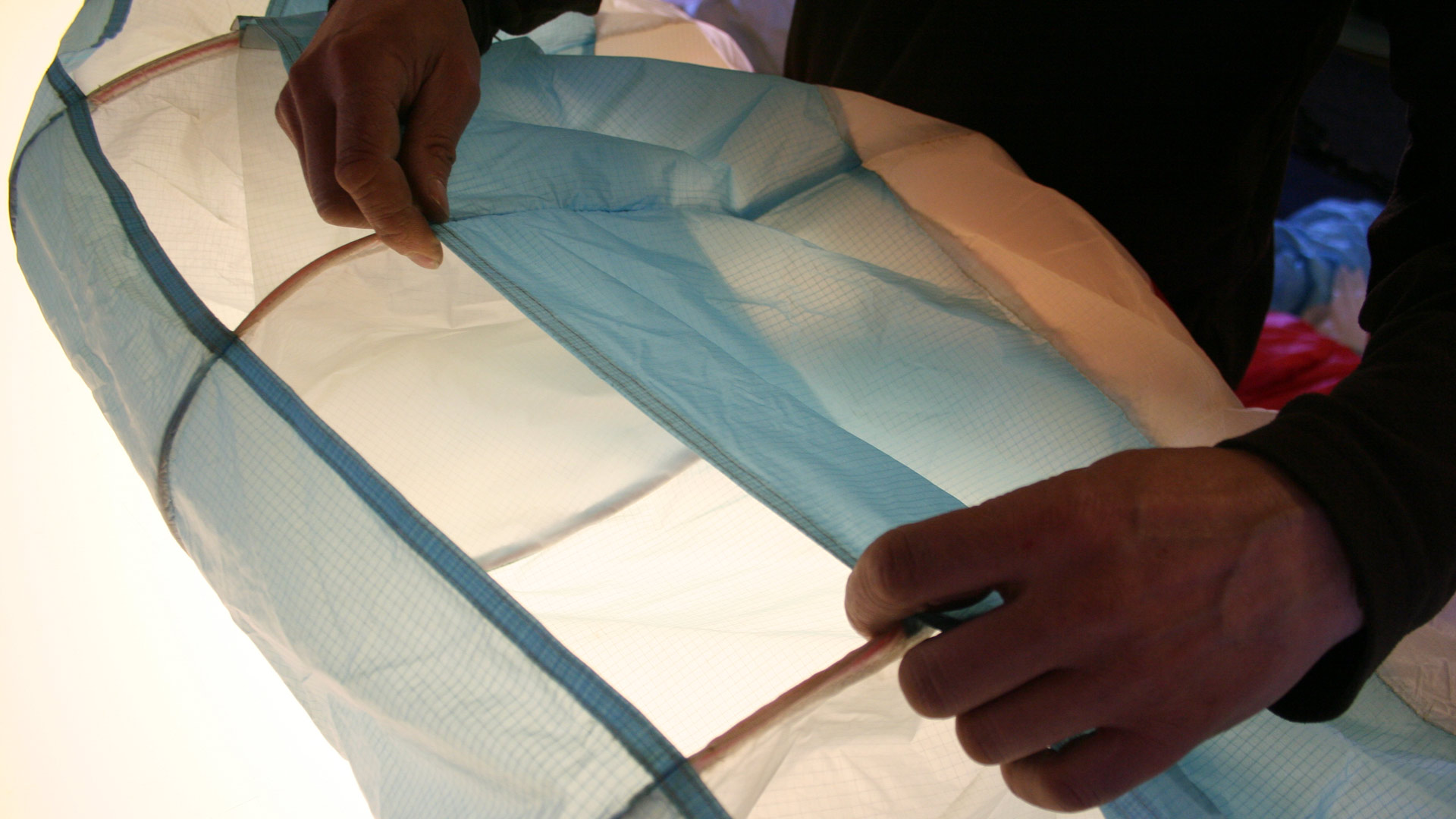

Visual check of the wing fabric using a light box. This allows for small holes to be seen much more easily, as well as scratches where the fabric can start pulling apart, any issues with the weave of the cloth itself Scuffing and abrasion. Particular care is given to the batton area where any dragging will cause damage very quickly.

Inside the cells ribs and bracing are checked and any debris removed.

Line breaking destruction strength test on 3 years and older wings on the main A and further lines if necessary.

Fabric Porosity test, this is performed using a JDC porosimeter on the leading edge of the wing.

Visual check of risers, pulleys (lubricated if required), brake handles, line loops, wear at the maillon connection points.

With the Full Trim service, a complete line length check is carried out using a laser measuring device, line shrinkage or stretching is checked and compensated for to return the wing to a trim at the manufacturers specification. With our 9 years’ experience using the Nova line measuring system we have taken this knowledge and use it on all other makes, Skywalk also have their own system which we now use after a visit to their HQ earlier in the year.

A service is recommended every 2 years or 100 hours, whichever comes first. Whether it’s a Standard or Full Trim service is a matter of personal preference, but the trim is possibly the most important aspect of the service. An out of trim glider can suffer deterioration in any of its flight characteristics, including:

- Symmetry

- Collapse behaviour

- Trim speed

- Glide ratio

- Stall behaviour

- Overall efficiency

Considering all these possible parameters the benefits of a Full Trim service become more obvious. Also, depending upon the manufacturer and the tolerances they work to, it may be the case that a full trim improves upon the tolerances the wing was shipped with. At the very least you can fly with confidence that your wing is going to be performing at its best.

The actual check does vary by manufacturer and depends upon the material, here Mikes long experience really pays dividends, as he is familiar with the pros and cons and areas of weakness of each design.

Is it still worth doing the old trick of trimming a glider by stretching the lines out?

Not really. Kevlar doesn’t generally shrink, but can lose strength hence the line strength test. For a wing with Dyneema which stays strong but can shrink over time, it may be useful as a temporary measure, but as the line will quickly return to its shrunk length, it’s far better to have it properly trimmed by adjusting the length of the lines.

Mike, you are a well-known pioneer of the paragliding scene in the South of England; What are your claims to fame?

Along with Mark Turner, I was the first pilot ever to fly a paraglider to the Isle of Wight from Combe Gibbet, I also held many local site records in the early days.

You spend all day looking at lines and cloth, at night do you dream of maintaining paragliders?

Thankfully no!

Mike's top tips for looking after paraglider wings

- Don’t drag the wing – this will wear through the baton area very quickly and it’s an expensive repair

- Minimise UV exposure

- Make sure its dried out properly if it gets damp or wet

- Use your butt holes! (To get the debris out of the wing)

- Keep off the barbed wire!!

Dickon's experience at the Loft

During my time in Newhaven I had my own Advance Iota wing, checked and serviced, my reserve checked and repacked and harness checked and repaired.

Mike replaced 3 brake lines on my wing - these had worn where they gather through the rings near the tips. Otherwise, my 2 and half year-old / 130 hours Iota was still in very good shape despite being of semi-light construction, giving an excellent porosity rating and having no holes. I’d give more credit to the fabric and manufacturing processes used than my fastidious care, which shows that wing design and manufacture has progressed to improve reliability over the years.

The three-year-old Ozone Ozium harness had not stood up to the test of time quite so well however, having torn and significantly affecting the structure of the harness where the speed system is attached, thereby making symmetric acceleration impossible. Mike repaired this at short notice with a piece of webbing for reinforcement.

The reserve repack was surprisingly simple, however with 20-years-experience, Mike's familiarity made it seem particularly easy. I can now fly for the next year feeling reassured knowing the reserve has been packed by an expert and will open in the shortest possible time if required.

As it is somewhat costly and requires being without a wing for a short period some pilots can be tempted to skip servicing, and particularly the Trim Service as it is a more expensive option. I recently met a pilot in the landing field who without my even mentioning wing servicing, volunteered the information that his 8-year-old wing (which he had bought with no service history) was demonstrating an unnerving tendency to collapse even in calm conditions.

So, in conclusion if you are flying an older wing, or any wing due a service come to that, I’d certainly recommend a service as worthwhile. There are plenty of gliders out there in a less than optimum trim state and it really is better not to be flying one of them…

With many thanks to Mike Millwood and all the team at The Loft Workshop.

Brought to you by Flybubble

Want to see more? There’s no better way to support our efforts than buying from us. We’ll ensure you get great service! Choose from our great range AND enable us to produce more videos and articles to benefit the freeflight community.