A summary of the main Niviuk Paraglider Technologies which go into Niviuk paragliders and harnesses, from 3DL to TNT.

Evolution and constant improving is the guiding principle of Niviuk’s R&D team: "Thanks to the new technologies created over recent years, we have conceived new, more evolved and higher performing gliders." The Niviuk design team have a thorough and complete understanding of aerodynamic physics and they apply that knowledge to all of their products. Technology is a top priority for Niviuk: "For us, giving importance to small details means keeping focused on technology as a priority to provide the highest levels of innovation and quality to pilots. Constantly innovating, we always are on the hunt, looking for the latest and best materials to helps us design optimal products."

Niviuk Paraglider Technologies

Niviuk Paraglider Technologies covered here:

- 3DL (3D Leading Edge)

- 3DP (3D Pattern Cut Optimisation)

- DES (Double Effect System)

- DRS (Drag Reduction Structure)

- ELS (Ear Lock System)

- IKS Connect (Interlock System) 1000 & 3000

- RAM Air Intake

- RIS (Rear Inflatable Stabiliser)

- RSD (Radial Sliced Diagonal)

- RSP (Reflex System Profile)

- SLE (Structured Leading Edge)

- STE (Structured Trailing Edge)

- TNT (Titanium & Nickel Technology, Nitinol)

3DL (3D Leading Edge)

Adding an extra seam to the leading edge on the span axis of the glider helps to shape a compact 3D profile and have better connections to the new 3DP front panel’s layout.

When sewn together, the fabric pattern orientation and panel positioning are taken into account to avoid creases and ultimately obtain a perfect load distribution. As a result the glider profile is cleaner, to the benefit of performance and durability.

The application of this innovation to the profile is key to reaching the perfect shape from 2D to 3D.

3DP (3D Pattern Cut Optimisation)

Our paragliding and paramotor wing designs have changed significantly over time; hence considerably affecting the leading edge shape. The latest glider generation requires a new pattern design and an optimised fabric cutting process.

The new leading edge arrangement calls for each cell panel to be manufactured independently from the others according to the final wing layout positioning, resulting in a crease-free surface with better fabric tension. We could use the analogy of a rugby ball made of different sewn individually shaped panels to obtain the perfect characteristic oval shape without wrinkles.

An optimised process is used to cut the fabric in a specific directional angle, depending on each panel’s final location. If the cloth pattern is correctly aligned with the load axis, the material is deformed to a minor degree to benefit the aerodynamic properties of the leading edge.

The application of this innovation, together with the 3DL, is key for reaching the optimal modelled form and function from 2D to 3D.

DES (Double Effect System)

With the implementation of the DES pilot can make the most out of the glider‘s ability to perform to its full potential using the speed bar.

The DES keeps the trims in a closed position (the slowest) by default, and will open when accelerating during the flight.

When the accelerator is released the DES brings the profile back to the neutral and default position.

DRS (Drag Reduction Structure)

With the Drag reduction Structure technology, the trailing edge has been reinforced with small ribs that that makes this part of the glider flatter in order to spread the pressure out evenly. It means better air-flow and less drag on this important part of the glider.

The addition of these small ribs gives the glider exceptional handling (better and more efficient when turning) and more control and precision. We are convinced that the key to achieve better products is the innovation. Only if we go on looking for new possibilities, we will be able to reach our main goal: enhance the experience of the pilots.

ELS (Ear Lock System)

The application of “Ears” provides a method of descending moderately at around -3 to -4 m/s. Applying ears increases the angle of attack of the wing and also the loading of the remaining open surface.

When the ears are applied it must be appreciated that the ground speed will reduce by 3 to 5 km/h and in order to maintain this descent technique, the pilot must continue to physically hold in the ears. This action therefore removes the ability of the pilot to apply active piloting to the wing and the only safe means of direction control available is the use of weight shift. If ears are applied for any considerable length of time, pilot fatigue could also become an issue. During a tandem/dual flight, even the assistance of an active passenger cannot fully alleviate these issues.

Whilst a solo pilot is applying ears, the angle of attack can be reduced and horizontal/forward speed easily increased by use of the speed (bar) system. This is not an option for a tandem/dual pilot and if holding in the ears by conventional methods, access to the trimmers is also obviously restricted.

These problems have been recognised by NIVIUK Gliders and as a result they have developed the EAR LOCK SYSTEM. (ELS).

The Ear Lock System is standard equipment on the TAKOO 3. This system provides a simple and effective solution for the tandem/dual pilot when quick descents are required with the use of ears.

ELS features / advantages:

- enables the pilot to lock and unlock the ears as desired.

- gives full control to the pilot with the ears applied.

- lets the pilot use the ears as long as necessary with no physical effort at all.

- allows the pilot to use the trimmers without concern or restriction.

- locks in the ears and prevents accidental opening.

- still allows the conventional application of ears (it is optional)

- can easily be uninstalled without affecting the rest of the equipment.

Ears (ELS) ON - Simply take the ear line and pull it downward until the knot passes through the ELS (lock system); then move it slightly horizontally forward, locking the knot in the V groove.

Ears (ELS) OFF – To Release, pull the ear line down and release the knot from the V groove. Then guide it vertically as it goes upward and back through the ELS (Lock System)

It is better to release the two ears separately. To perform the ears as a descent manoeuvre in the classic way, take the external A line on both sides, as high as possible and pull them downward and outward. You will see the wingtips fold down. To reopen them, release the lines and they will reopen by without assistance. If this does not happen, brake progressively on one side and then the other. Asymmetric reopening is recommended in order to avoid compromising the angle of attack, particularly flying near the ground or in turbulent conditions.

IKS Connect (Interlock System) 1000 & 3000

The IKS (Interlock System) is an ultra-lightweight, high strength connecting system that aims to complement the light product range and replace the current systems based on the use of the maillons and/or carabiners. This new system is based on a secure connection using a simple Dyneema loop provided with a fixing and locking system, ensuring the complete efficiency and safety of the connection, and allowing the equipment to be ready at all times, either with or without load.

Niviuk has developed two types - the IKS1000 and the IKS3000, each one designed as a connection system for different parts of the wing.

The IKS1000 is designed and dimensioned as a connection system between the risers and the lines. It has a breaking load of 1055 kg, which greatly exceeds that of the classic 3mm (550 kg) maillon, but with a much less weight. This feature makes it a key element in the entire range of P-Series (lightweight) wings, which are delivered with this technology as standard.

The IKS3000 is designed to connect the risers and/or the parachute with the harness. Its breaking load of 2960kg makes it an ultralight alternative to the 7mm (3125 kg) maillon or an aluminium carabiner (2000 kg). The IKS3000 design and concept make it ideal for mountaineering, hike & fly and ultralight equipment.

In short, the IKS technology is an advance towards a greater lightness in wings and equipment, without losing effectiveness and providing a a high degree of safety and strength.

Comparative technical data:

| Item | Weight | Breaking load |

| Niviuk IKS1000 | 1.9 g | 1055 kg |

| 3mm maillon | 6 g | 550 kg |

| Niviuk IKS3000 | 9 g | 2960 kg |

| Aluminium carabiner | 62 g | 2000 kg |

| 7 mm maillon | 64 g | 3125 kg |

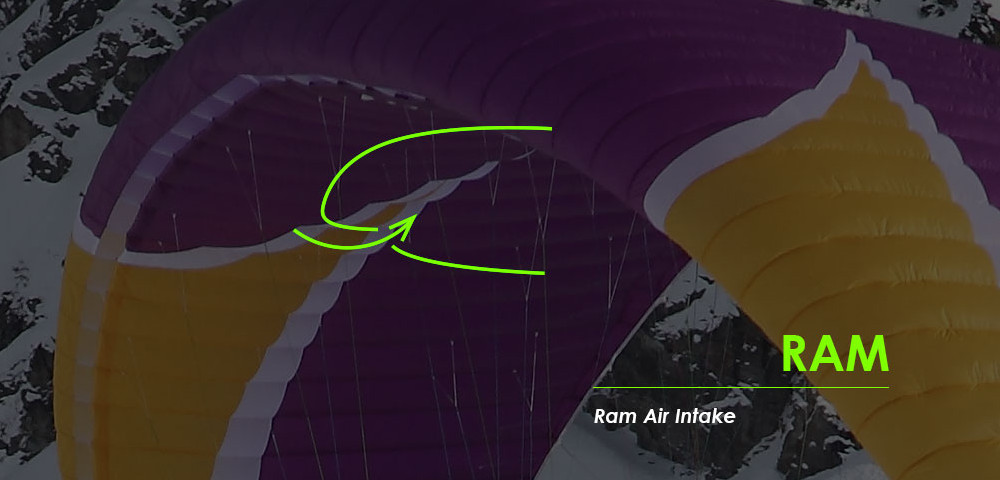

RAM Air Intake

The RAM Air Intake system is characterised by the arrangement of the air inlets, to ensure optimal maintenance of internal pressure. Thanks to this design, we were able to reduce their size, while maintaining the same air flow at all angles to improve laminar flow. The result? Having greater internal pressure means better absorption of turbulence, greater consistency of the profile across the speed range, excellent handling at low speed is achieved by allowing the pilot to extend the braking limit, there is a lower risk of collapse and consequently, greater control and stability.

RIS (Rear Inflatable Stabiliser)

The Niviuk design team have applied their all of their aerodynamic physics knowledge to the competition and cross country harness, the DRIFTER.

The new and innovative Rear Inflatable Stabiliser (RIS) maintains maximum aerodynamic efficiency at all times resulting in increased overall performance of the wing with improved glide and sink rates. The RIS ensures the departure of disruptive airflow is as far away as possible from the main body of the harness thus reducing unwanted and counterproductive turbulence.

The RIS is inflated by way of two lateral air intake ducts, each positioned in an area which is permanently fuelled, so avoiding unwanted deflation by any loss of air feed. Even whilst the pilot is entering the “cockpit” (pilot´s cabin) the RIS remains in continuous operation, maintaining the aerodynamic profile without deformation or loss of efficiency.

RSD (Radial Sliced Diagonal)

Radial Sliced Diagonal (RSD) technology is a reinvention of the wing's internal structure. This new design is based on individual diagonal panels arranged in radial form, which increase the efficiency of the internal structure considerably.

Each of the current diagonals has been divided into three independent strips with different working angles. Therefore it is possible to optimise the orientation of the strips towards the internal tension of the attachment points and to reduce the deformation of the sailcloth, which is caused by loads contrary to the working axes of the fabric.

Load distribution in flight

Conventional diagonals (without RSD):

With Radial Sliced Diagonals (RSD):

With RSD, the flying experience of the pilot will be greatly improved, thanks to the reduction of inertia and sail deformations, as well as making the overall weight of the wing much lighter.

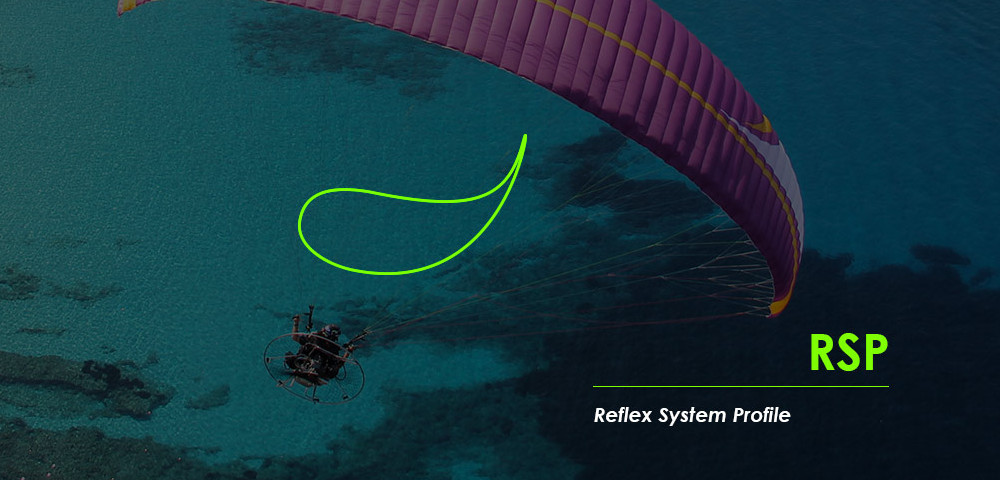

RSP (Reflex System Profile)

The highly efficient Reflex System Profile (RSP) unlike conventional reflex designs requires less engine power to achieve greater thrust, thus resulting in lower fuel consumption, more autonomy and higher overall motor efficiency.

The RSP profile improves gliding, speed and safety.

SLE (Structured Leading Edge)

The SLE provides more rigidity and stability along the span of leading edge but also allows full flexibility along the both the vertical and horizontal axis of each open cell. The SLE ensures ease of movement on the ground and high security in the air during turbulence and whilst flying at speed.

With the SLE system there is no longer a need to use large amounts of mylar material to achieve leading edge reinforcement. This reduction in material has reduced the weight of the leading edge and the result is precise handling on the ground and easier launches. The SLE also helps to prevent deformation of the leading edge mylars and therefore with correct care will extend the life and efficiency of your glider.

In addition to the SLE, we work on new geometry and layout of the internal reinforcement. This new internal re structuring offers better overall cohesion of the glider and incredible stability during turbulence.

STE (Structured Trailing Edge)

The STE optimises the profile without deforming it. We can thus obtain less resistance and better performance.

With the STE, the circulation of the air is more fluid, maintaining a consistent airflow at the trailing edge, and obtaining a cleaner airflow at high speeds. When we reduce the speed of the wing, it is its entire surface which slowly starts to bend, not only its trailing edge, as happens with the wings that do not have STE. The pitch control is notably improved as well. When in flight we accelerate the glider, the profile keeps more balanced, giving to the wing more stability, especially in the trailing edge. STE works on more surface of the wing without distorting the profile.

STE: a new concept of state of the art technology applied to the Niviuk Serial wings.

TNT (Titanium & Nickel Technology, Nitinol)

Constantly innovating, always are on the hunt, looking for the latest and best materials to help design optimal products, and after an extensive evaluation of its benefits and qualities, Niviuk decided to be the firsts manufacturer to use Nitinol in their gliders.

Benefits

Nitinol is an alloy of 50% nickel and 50% titanium. This technology in our rods offers three major advantages of optimising the performance of a paraglider, compared to those made out of Nylon:

- The addition of Nitinol rods in the profile, has the immediate result of substantially reducing the overall weight of the wing by about 13%.

- Nitinol has two very specific properties: shape memory and super elasticity. The flexible rods always regain their functional optimal shape, even after tight bending, no wrinkles or residual mechanical alterations affect their integrity.

- As a result, the wing's leading edge is then preformed on the ground and allows a uniform progressive inflation phase to take place, which considerably facilitates the takeoff. The wing surface is perfectly taut, wrinkle free and without parasitic cloth movements, the glide is thus optimised in all flight phases.

In addition, the rods are outfitted with plastic protectors at their ends to prevent fabric damage.

See all current Niviuk paragliders